The two latest case studies from Chem-Trend show real-life production gains through Chem-Trend technologies. The case stories show how costumers have solved their challenges and improved their processes through the support of Chem-Trend expertise. First case study demonstrates how a 95% reduction in downtime for cleaning was achieved by making one significant change with Ultra Purge™ purging compounds. The second case study illustrates how an injection molder cut mold maintenance hours, reduced scrap rates and improved surface quality with Lusin® mold cleaner.

The true strength of Ultra Purge™

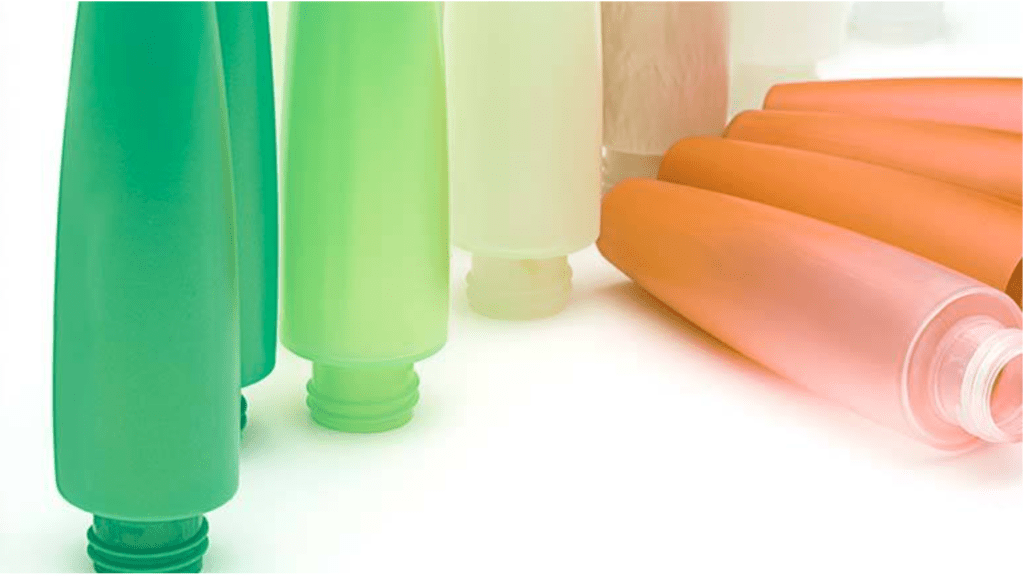

Chem-Trend’s technology Ultra Purge™ helped a cosmetic packaging company make up for significant cleaning downtime.

A European cosmetics packaging company was experiencing significant downtime in their production process. Stoppage for cleaning during color changeover from cosmetic containers was particularly challenging and caused a cumulative standstill of up to 10 hours monthly.

By using Ultra Purge™ to clean the machine, the manufacturer achieved a 95% reduction in downtime for cleaning and a minimized scrap rate. Furthermore, the manufacturer reduced the total amount of virgin resin needed for the purging process contributing to material cost savings.

The full case study is available here.

Eliminate buildup in injection molding with Lusin® MC1718

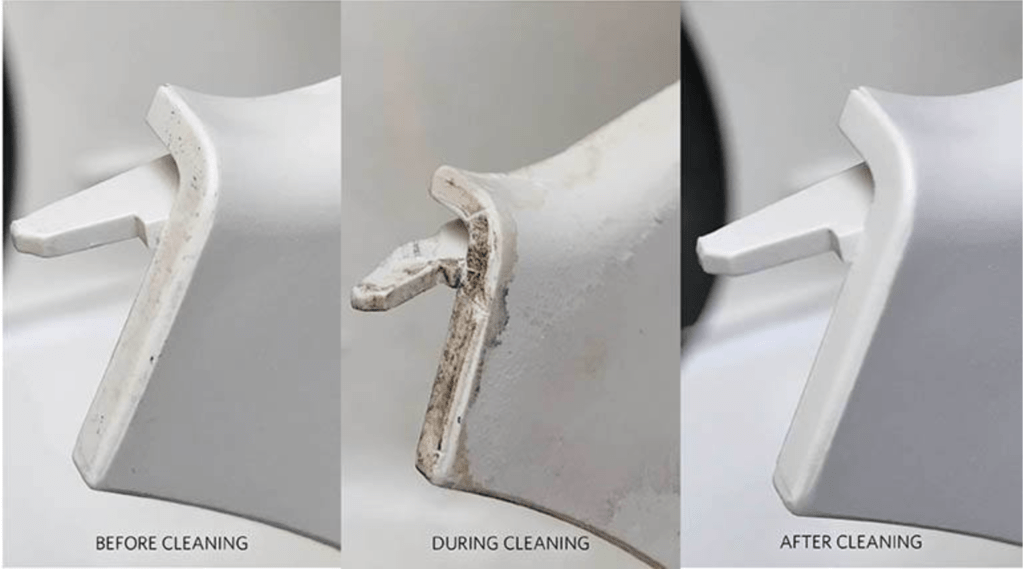

A custom injection molder of heavy, surface sensitive white parts cut mold maintenance hours, reduced scrap rates and improved part surface quality by using Lusin® MC1718.

In this case, careful and labor-intensive refurbishing was necessary every two weeks due to heavy buildup of residues in the mold cavities. Lusin® MC1718 was tested given its proven capability to substantially minimize buildup in the mold.

The product was applied directly to the mold cavity. After some reacting time, polymer buildups were softened and pulled from the mold through the process of producing parts. This method allowed quick and easy cleaning and extended the time between cleaning cycles to six weeks.

The full case study is available here.

Bjørn Thorsen – Distributor of Chem-Trend products

Bjørn Thorsen is the official distributor of Ultra Purge™ purging compounds and Lusin® mold cleaners in Denmark, Sweden, Norway, Finland, Estonia, Latvia and Lithuania. For more information about the products and orders, please contact Claus Jørn Jespersen at cjj@bjorn-thorsen.com.